1. Requirements for organic fertilizer packaging

Organic fertilizer packaging needs to ensure the following elements:

Ensures durability, toughness, solidity, good bearing capacity, and no stretching during transportation.

Has good waterproofing and moisture resistance to protect the fertilizer inside from being affected by external factors.

Information on the product has beautiful packaging, impressive colors, and clear printing.

Guaranteed quality, does not affect the quality of fertilizer such as damage or deterioration.

Environmentally friendly, easily recycled, and decomposed to minimize impact on the environment.

Organic fertilizer bags must meet the requirements of durability, good bearing capacity, and waterproofing.

2. Types of packaging for organic fertilizers

Commonly used types of organic fertilizer packaging include:

2.1 PP Fertilizer Bags

PP bags are a type of packaging commonly used in storing organic fertilizers in granular or pellet form. PP (Polypropylene) material is a type of plastic with high durability, good waterproofing, resistance to high temperature and pressure, and not affected by external environmental factors or chemical agents.

At Green Packaging, we provide single woven PP fertilizer bags and laminated-coated fertilizer bags.

Single woven PP fertilizer bag

- This is a weaving method used as plaid with flexo printing technology, applied to contain commercial fertilizers domestically and for export.

- The common single woven PP packaging specification is usually 2-stitch bottom sewing, open mouth, depending on customer needs and type of goods, whether there is a PE cage or not.

- Single woven PP bags are considered a type of packaging with good mechanical properties, ensuring safety when storing, containing, and circulating domestically as well as exporting.

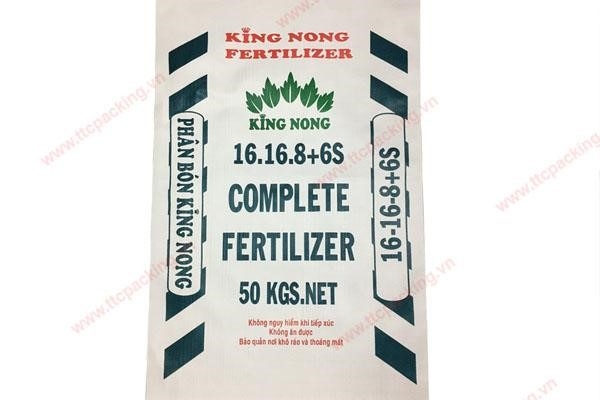

Laminated Fertilizer Bags

- Woven PP bags laminated with OPP (Oriented Polypropylene) film, also known as BOPP (Biaxial Oriented Polypropylene) bags, are high-quality organic fertilizer packaging.

- At Green Packaging, this type of organic fertilizer packaging is produced using Flexo and Gravure printing technology, along with a Starlinger machine system imported directly from Europe, so they achieve aesthetics. High comes with outstanding quality.

- The structure of this COE compost packaging includes PP woven fabric + PP coated glue + OPP (Oriented Polypropylene) film.

- The woven PP fabric layer is highly durable, strong, and tough to bear the load.

- The PP adhesive layer is used to attach the OPP film to the woven PP fabric.

- The OPP membrane has a waterproofing effect, protecting the organic fertilizer inside from damage. At the same time, with this membrane layer, the packaging aesthetics are higher because it allows gravure printing with sharp and vivid printing content.

At Green Packaging, there are 2 types of organic fertilizer packaging commonly used: Woven PP Fertilizer Bags and Laminated Laminated Fertilizer Bags.

2.2 Kraft paper packaging

This type of packaging is made from kraft paper and has the characteristics of good strength, easy recycling, and environmental friendliness. The application of this type of packaging is to store microbial fertilizers, and organic fertilizers in solid or pellet form. However, it cannot hold highly corrosive fertilizers. At the same time, it is not waterproof to water or air, is easily damaged if exposed to water, and will become moldy if left for a long time.

2.3 PE organic fertilizer packaging

PE bags are organic fertilizer packaging made from polyethylene plastic, with good flexibility and elasticity. In addition, this material allows good water and gas resistance, preventing chemical agents from affecting the goods inside. This type of bag is used to store organic fertilizers in liquid or gel form.

However, this type of packaging has the disadvantage that the durability of the ink is not high. When exposed to agents such as hard objects, it can easily be scratched or blurred, affecting the information on the packaging. PE bags are also not environmentally friendly because the material is difficult to recycle.

3. Common Sizes of Organic Fertilizer Packaging

The sizes of organic fertilizer packaging include 5kg, 10kg, 20kg, 25kg, and 50kg. The most popular size is 50kg because this is the most suitable load for packaging to contain organic fertilizer, meeting the needs of users.

4. Green Packaging - Specializes in Providing Diverse Organic Fertilizer Packaging Designs for the Australian Market

Green Packaging is a unit specializing in providing a variety of organic fertilizer bags, ensuring to meet all quality and design requirements of customers. With advanced technology imported directly from Europe and modern production lines, Green Packaging is committed to bringing the highest satisfaction to domestic customers and international markets, especially Australia. With 22 years of experience, we understand the strict standards of the Australian market to produce products that meet quality standards, legal regulations, and export procedures.

In addition, with products in the high-end fertilizer segment, Green Packaging uses modern copper shaft printing technology, making the colors on the packaging more realistic and clearer. Customers can change according to their needs, we will provide solutions that meet customer requirements.

Green Packaging is ready to advise and support you on packaging structure options to ensure optimal strength, aesthetics, and cost savings.

Please contact Green Packaging immediately if you need to find a supplier of organic fertilizer packaging designs according to the Hotline: 0961 416 688 - (0267) 3822 426.