HOW IMPORTANT IS THE SAFETY FACTOR IN EXPORT PACKAGING STANDARDS?

Jumbo bags (also known as big bags / Bulk bags / FIBC) are large-sized bags made of PP (polypropylene) woven fabric with high load-bearing capacity, specifically designed for storing, handling, and transporting goods with a load capacity ranging from 500kg to 2500kg.

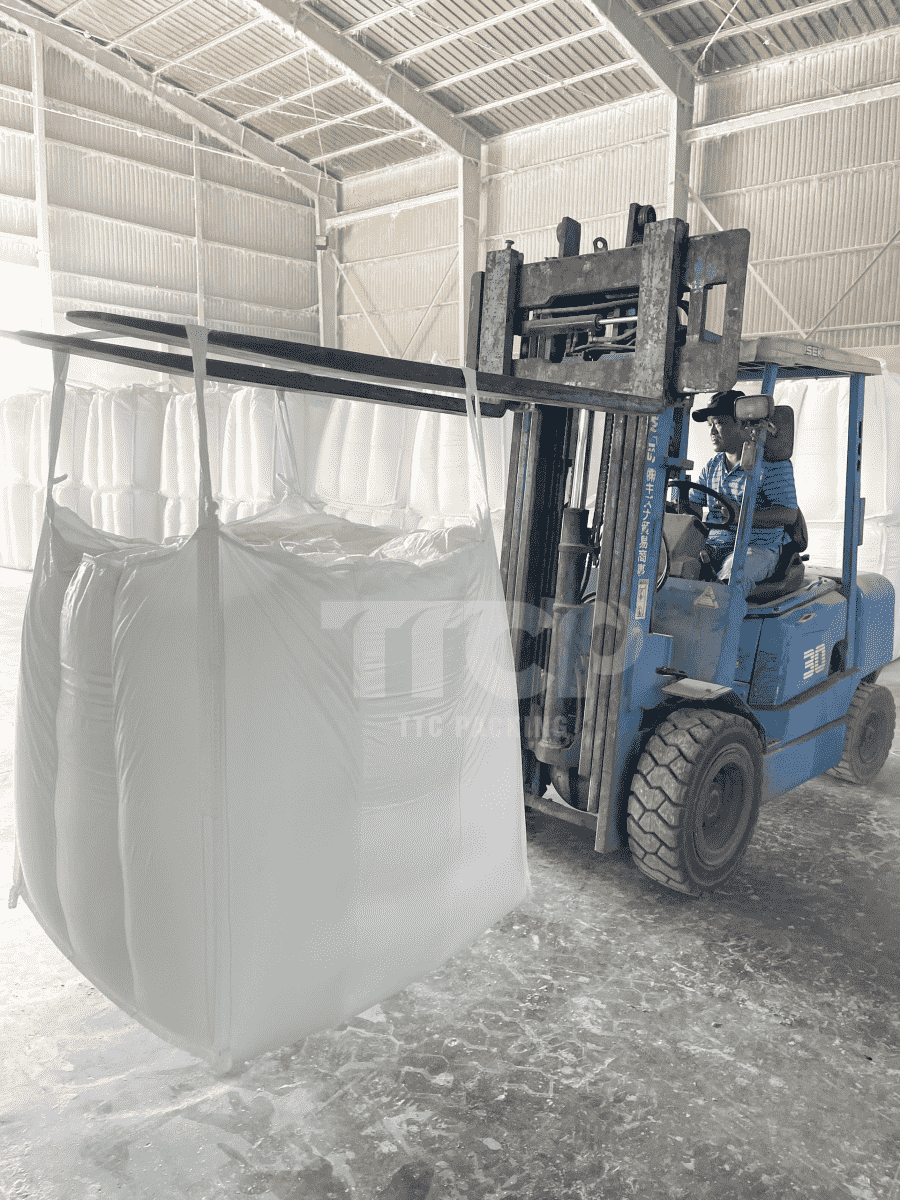

Jumbo Bag in cargo transportation

Two important factors that a Jumbo bag must meet before being put into use are SWL - Safe Working Load and SF - Safety Factor.

So what is the safety factor?

The safety factor of a jumbo bag is the load-bearing capacity or the limit state of the bag against external influences that are not controlled during use.

Currently, safety factors range from 3:1, 4:1, 5:1, 6:1, 7:1, 8:1. The safety factors commonly used for high-quality jumbo bags (according to ISO 21898) are 5:1 and 6:1.

The 5:1 safety factor is the standard for single-use jumbo bags (single trip) with one cycle including loading cargo - storage in the warehouse - transportation - unloading cargo from the bag. When this standard is achieved, the bag is capable of withstanding a load five times its designed load.

The 6:1 safety factor is required for multiple-use jumbo bags (multiple trips). It involves multiple cycles of loading cargo - storage - transportation - unloading cargo until the bag shows signs of wear or tear.

For example, a jumbo bag sized 90cm x 90cm x 110cm is designed to hold 1000kg.

So, the Safe Working Load - effective load capacity of this bag is 1000kg.

This bag achieves a 5:1 safety factor when tested as follows:

SF Testing Machine of Green Packaging

- Fully load the product into the bag with a working load of 1000kg.

- Install the bag into the testing device, which will exert double the working load on the bag, equivalent to 2000kg. The device will compress the bag 30 cycles with consistent timing. Then the device applies a force five times the working load. The bag achieves a 5:1 safety factor when in the final cycle, the force exceeds 5 times the working load, meaning over 5000kg.

Similarly, the bag achieves a 6:1 safety factor when the force exerted on the bag in the final cycle exceeds 6 times the working load of the bag, meaning over 6000kg.

Manufacturing jumbo bags according to the above safety factor standards aims to minimize risks during the use of bags due to external factors, incidents caused by errors during packing, transportation, etc. To meet these requirements, all materials, and production processes of jumbo bags must be synchronized in quality and strictly controlled technically.

Because of these factors, in markets like the US and Europe, jumbo bag users are particularly concerned about safety factors.

Green Packaging is committed to always testing and ensuring that bags meet the required standards before mass production.

Contact us now for more detailed advice:

------------------------------------------------------------------------------------------

GREEN PACKAGING JOINT STOCK COMPANY

- Head office: Lot 99, My Tho Industrial Park, Trung An Commune, My Tho City, Tien Giang Province.

- Tay Ninh Branch: 285 Tran Phu, Ninh Thanh Quarter, Ninh Son Ward, City. Tay Ninh, Tay Ninh.

- Representative office: 374 - 374B Vo Van Tan, Ward 5, District 3, City. HCM.

- 0961 416 688 - (0267) 3822 426

- Email: info@greenpackaging.vn