The process of producing Kraft paper packaging by flexo printing includes 7 main stages:

Pulling PP threads -> Weaving PP fabric -> Coating PP fabric/Kraft paper -> Printing -> Cutting, sticking, and shaping -> Sewing, forming finished products -> Inspection and packaging

Stage 1: Pulling PP threads

Virgin PP resin (mostly imported from Arabia) along with certain additive materials mixed in certain proportions are loaded into the hopper of the thread-making equipment, heated to melt, the liquid plastic is adjusted to the standard technical thickness.

The plastic film is formed through the cooling system, then the film goes to the slitting shaft to be cut into PP threads.

PP threads go through the heating section to stabilize the threads and then go to the rolling machine to form PP thread bobbins.

Stage 2: Weaving PP fabric

The PP thread bobbins are passed through the weaving machine system, including 6 weaving spindles, the horizontal and vertical threads are interwoven to form PP fabric tubes.

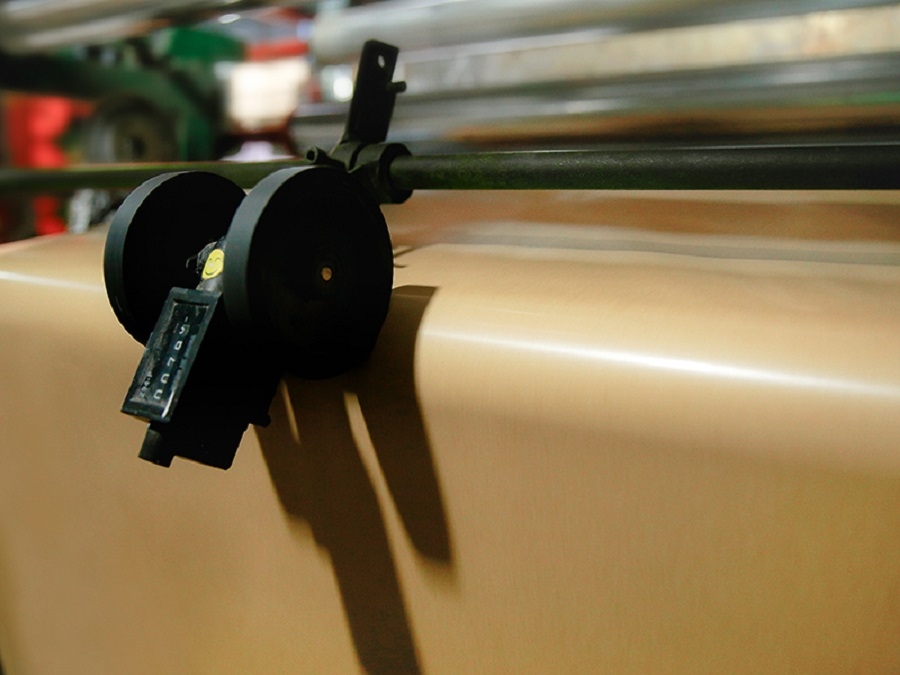

Then, the PP fabric tubes are slit into sheets through the rolling mechanism to form PP woven fabric rolls.

Stage 3: Coating PP fabric/Kraft paper

The PP woven fabric roll at stage 2 (in roll form) is passed through the coating machine, to be combined with Kraft paper (in roll form) through the PP coating layer to form complex rolls: PP/Kraft paper (or KP).

Stage 4: Printing

The complex roll KP is passed through the printing machine, flexo printing based on the approved design with the customer through the printing plate made of Polymer material.

Stage 5: Cutting, sticking, and shaping

The printed KP roll is passed through the cutting and sticking machine to shape and cut to the agreed size with the customer. At this stage, the relative packaging shape is formed.

At this stage, depending on the characteristics of some specific products, packaging used for the chemical industry, construction, etc., will have an additional layer of Kraft paper inside to enhance moisture resistance for the product.

Stage 6: Sewing, forming finished products

The packaging cut from stage 5 is sewn in the form of bottom seam, leaving the remaining head open for the customer to close the product.

Depending on the nature of each product, additional stages may be added to insert PE bag to enhance absolute heat resistance for the packaged product.

For some products in the construction industry, depending on the packaging technology of the customer, the packaging will be sewn on both ends, fold the valve mouth to increase the packaging productivity of the product.

Stage 7: Inspection and packaging

The completed packaging will be inspected by quality control staff for form - quality and packed in accordance with the specifications before being delivered to the customer.

------------------------------------------------------------------------------------------

GREEN PACKAGING JOINT STOCK COMPANY

- Head office: Lot 99, My Tho Industrial Park, Trung An Commune, My Tho City, Tien Giang Province.

- Tay Ninh Branch: 285 Tran Phu, Ninh Thanh Quarter, Ninh Son Ward, City. Tay Ninh, Tay Ninh.

- Representative office: 374 - 374B Vo Van Tan, Ward 5, District 3, City. HCM.

- 0961 416 688 - (0267) 3822 426

- Email: info@greenpackaging.vn