With the development of the economy and production-consumption activities, packaging is increasingly used with diverse materials and designs. However, most of the packaging materials currently used have a significant environmental impact due to their long decomposition time.

Kraft paper is a type of paper created by the kraft process from softwood. Kraft paper is made into packaging with appropriate weight and layers for the contained products.

Kraft paper is a type of paper created by the kraft process from softwood

In Vietnam, kraft paper bags have long been used and are commonly referred to as "cement bags" because they are widely used to hold cement. Nowadays, kraft paper can be combined with other materials to make packaging for products ranging from a few hundred grams to 50 kg.

The most common kraft paper packaging used today is for products weighing from 5kg to 25kg, with the following characteristics:

- Color: Kraft paper typically comes in brown, grayish-yellow, or brownish-yellow, depending on the type and origin of the paper. Additionally, kraft paper also comes in white.

- Origin: In addition to Vietnamese kraft paper, the domestic packaging market mainly uses imported kraft paper such as Japanese kraft, Korean kraft, Russian kraft, American kraft, etc. The most popular is Japanese kraft.

- Basis weight: Kraft paper comes in various basis weights, depending on the packaging function, the manufacturer will choose the appropriate paper weight: 60gsm, 70gsm, 80gsm, 90gsm. For kraft paper packaging weighing from 5-25kg, the most suitable basis weight is 70gsm.

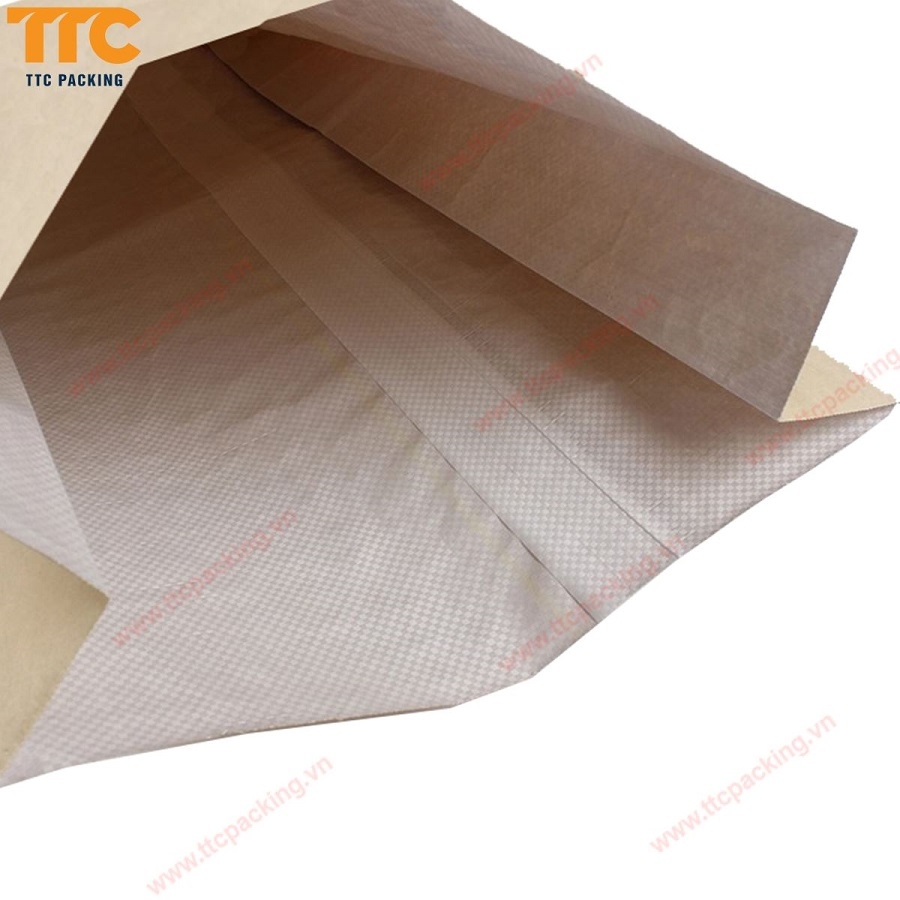

- Structure of kraft paper bags: Depending on the nature and weight of the contained product, kraft paper bags may have multiple layers or be laminated with other materials for suitability.

Kraft paper laminated with Al/MPET film, laminated with PE to create bags from 100g to 1kg for products such as coffee, tea, food, etc.

2-4 ply kraft paper bags for various granular or powdered food products weighing from 5kg to 25kg.

Kraft paper laminated with woven PP (KP bags) is used for a variety of goods from 5kg to 40kg.

Kraft paper laminated with woven PP

Types of kraft paper packaging:

- Kraft paper bags laminated with film materials often create bags with similar specifications to those of complex laminated film packaging, such as 3-side seal bags, gusseted bags, 4-side seal bags, bottom gusset stand-up pouches, etc.

- 1-4 ply kraft paper bags are formed into bags using edge gluing, bottom gluing, or side gusseting, and can be box pouches.

- Kraft paper bags laminated with woven PP (KP bags) are formed into bags using bottom gluing, open mouth or valve formation, overtap sealing, and can be box pouches.

- For kraft paper bags or KP bags with open mouths, the packaging supplier will provide roll or separate cut mouth tapes for customers to seal the bags.

Types of kraft paper packaging: currently available

Printing: Kraft paper packaging is usually printed using flexo and offset printing technologies with 1-4 colors. With good ink adhesion properties, the printed patterns have high sharpness.

Why is kraft paper packaging the packaging solution for the future???

Why is kraft paper packaging the packaging solution for the future

Kraft paper packaging is flexible, durable, waterproof, and has good moisture absorption, ensuring its role in storing and preserving goods.

Kraft paper is easily biodegradable and does not harm the environment.

The rustic and familiar nature of kraft paper combined with the printing technology of packaging suppliers creates impressions and drives purchasing activities.

Kraft paper packaging is currently widely used for packaging food, agricultural products, chemicals, etc. This packaging solution is developing and becoming a trend for the future.

------------------------------------------------------------------------------------------

GREEN PACKAGING JOINT STOCK COMPANY

- Head office: Lot 99, My Tho Industrial Park, Trung An Commune, My Tho City, Tien Giang Province.

- Tay Ninh Branch: 285 Tran Phu, Ninh Thanh Quarter, Ninh Son Ward, City. Tay Ninh, Tay Ninh.

- Representative office: 374 - 374B Vo Van Tan, Ward 5, District 3, City. HCM.

- 0961 416 688 - (0267) 3822 426

- Email: info@greenpackaging.vn