What is PP woven bag?

PP woven bag (tiếng Anh: PP woven bag) is a type of bag made from woven polypropylene fabric, primarily available in milk white or transparent colors. However, with the advancement of modern technology, PP woven bags are designed with various shapes and colors, providing many benefits to human life.

The PP woven bag product is a type of bag made from woven polypropylene fabric, primarily available in milk white or transparent colors. This type of bag can be printed using Flexographic printing technology or Rotogravure printing technology.

What is PP woven bag

How is woven PP fabric made?

PP is the abbreviation of the English word Polypropylene, a product of propylene polymerization reaction... has high mechanical properties, quite stiff, not ductile, not elongated, so it is made into fibers. It can be easily torn with a small cut or puncture.

- Rolled woven PP fabric or also known as pieces

- Transparent fiber, with high surface gloss, high printing ability, clear print.

- PP is colorless, odorless, tasteless, non-toxic. When burned, it has a pale blue flame, a plastic-like flowing stream, and a gradually burning smell similar to rubber.

- Due to its high physical properties, it helps plastic packaging withstand horizontal tension, vertical tension, pulling force, and impact force.

- PP woven fabric currently has 2 main types: transparent PP woven fabric and hollow PP woven fabric.

- Transparent fiber is pure PP woven fabric, with high surface gloss. In production, a small amount of additives is added to increase the separation ability of PP layers and reduce costs. Adding additives depends on the ratio to produce different PP qualities.

Currently, there is a high demand to combat counterfeit and poor-quality goods, so most customers prefer transparent fibers to see the products inside, the fewer additives, the better the quality of PP fabric.

Classification of PP woven bags

PP woven bags are classified according to the structure including single-layer PP bags (with only one layer) and multi-layer PP bags, meaning there are 2 layers or more. Single-layer PP bags are bags with only one woven PP layer coated with an additional layer of plastic.

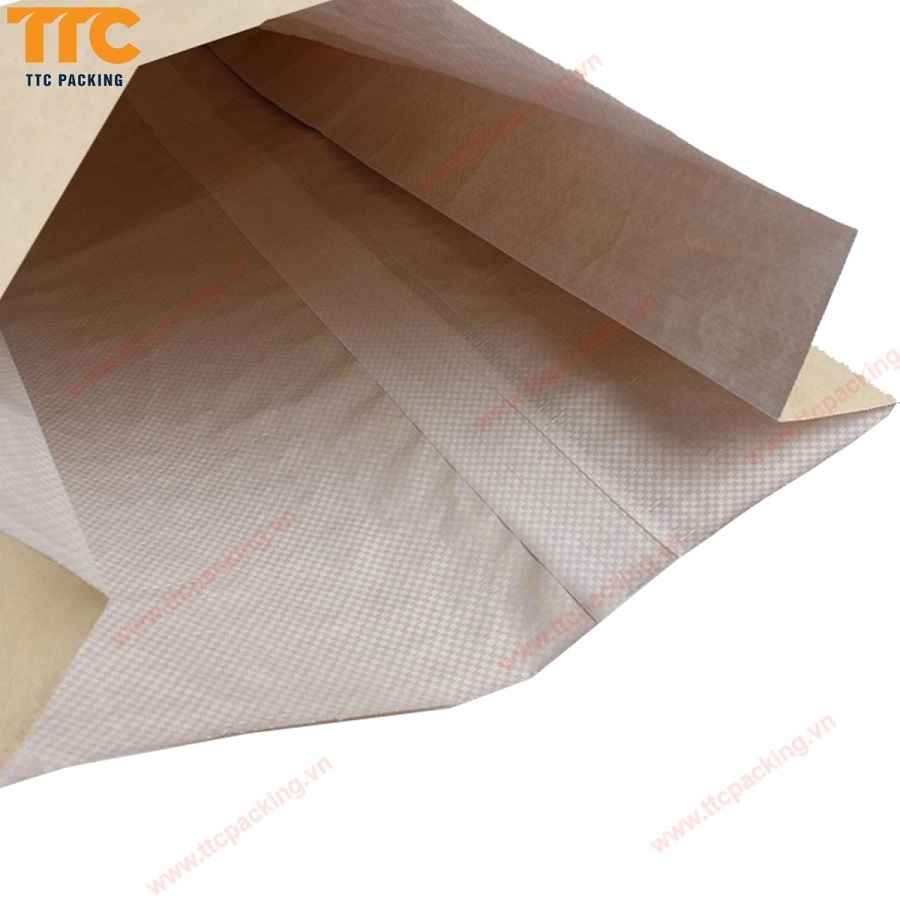

Multi-layer PP bags mean bags with 2 or more layers consisting of a woven PP layer laminated with a layer of BOPP film or magelize film or Kraft paper through a PP coated plastic layer.

Some types of PP woven products:

- Regular PP woven bag

- Adhesive-coated PP woven bag

- PP woven bag with laminated film

- PP woven bag with paper lamination

- PP woven bag for packaging goods

- Used PP woven bag, clearance

- PP woven bag with Kraft paper lamination

Kraft paper packaging is a technical term used by companies in the paper packaging industry, but for many people outside the industry, Kraft paper packaging is known as cement bags, of course, this is only a small part of the application of Kraft paper packaging today.

Various types of PP Woven Bags

PP WOVEN BAGS WITH PE LINER

PP woven bags are lined with PE bags inside to better protect or preserve products from moisture. PP woven bags with PE liners are the best packaging solution for storing fine powder products, products that need moisture resistance and impermeability. Because the liner bag acts to completely separate the product inside the bag from the outside environment.

ADHESIVE-COATED PP WOVEN BAGS

Adhesive-coated PP woven bags are made from virgin Polypropylene (PP) plastic woven with dimensions and thickness suitable for Customer needs and coated with a layer of PP glue.

BOPP Plastic Bags

BOPP plastic bags are a high-end multi-layer plastic bag line widely applied to various types of goods, including BOPP film layers gravure printed and laminated with PP woven fabric through a PP-coated plastic layer.

This is a product widely used in agriculture (fertilizers, seeds, rice bags, aquaculture, animal feed, etc.), and industry (construction additives, chemicals, etc.)

PP Woven Bag Printing Process

PP woven bags are commonly used in industries such as fertilizers, chemicals, food, animal husbandry, etc. However, to understand their structure, production process, most users do not fully understand. Let's explore more about the production process of PP woven bags:

PP fiber production: PP resin pellets are fed into the hopper of the fiber production equipment, sucked into the extruder by a vacuum, heated to melt, the plasticized screw extrudes the molten plastic, which is then formed into a length and thickness adjustable according to requirements, the plastic film is formed through a shaping water bath, the film enters the slitting knife to slit into fibers with a width according to requirements (2-3 mm), the fibers pass through a heating unit to stabilize the fibers then to the fiber winding machine. During the fiber production process, waste fiber, bavia of the plastic film is recovered by suction, cut, crushed and returned to the extruder.

PP fabric weaving: PP fibers are fed into a circular weaving machine with 04 weaving heads to weave into PP fabric tubes, which are then slit into PP fabric sheets through a rolling mechanism into PP fabric rolls.

PP fabric lamination: PP fabric rolls are transported by forklift to be mounted on the fabric lamination machine, PP fabric sheets are laminated with a 30-micron PP plastic layer to increase the bond of the fibers to resist moisture.

Bag tube forming system: PP fabric rolls that have been laminated and Kraft paper rolls are brought to the bag tube forming system. Here, the PP fabric is printed with the brand label then inserted into the Kraft paper strip and glued into tubes, through the tube cutting and valve forming system, the bag tubes are conveyed out through the conveyor belt.

Head sewing machine, bag closing: the bag tubes are evenly fed to the automatic valve folding system and to the head sewing machine, bag closing simultaneously through the chain conveyor system with grooves. Finished packaging products are conveyed out for palletizing.

Bag palletizing: The packaging products are inspected, compressed into bundles stacked on pallets, and transported by forklift to the storage warehouse.

PP bag structure

PP woven bags are made from white or transparent woven PP pieces. The bag fabric can be coated or uncoated, can be laminated with OPP film, and an additional PE liner bag can also be inserted inside to increase product protection. The size and load capacity of the bags are very diverse, customized to the needs of customers. Bags can hold from 5kg to 100kg.

Common Technical Specifications

- Length: According to customer requirements.

- Width: From 36 - 140cm or according to customer requirements.

- Weight/m: from 40gsm to 200 gsm or according to customer requirements.

- Weave: 10x10, 12x12, can be customized or according to customer requirements.

- Printing: On the surface or both sides in multi-colors. Flexo printing or gravure printing.

- Load capacity: 5kg - 50kg according to customer requirements.

Product Applications

PP woven bags are widely used for:

- Seeds like rice, cereals, wheat, and corn.

- Foodstuffs like wheat flour and sugar.

- Chemical products like fertilizers.

- Building materials like cement, sand, and powder.

- Animal feed like poultry and fish.

- Single-use for transporting garbage and construction waste.

------------------------------------------------------------------------------------------

GREEN PACKAGING JOINT STOCK COMPANY

- Head office: Lot 99, My Tho Industrial Park, Trung An Commune, My Tho City, Tien Giang Province.

- Tay Ninh Branch: 285 Tran Phu, Ninh Thanh Quarter, Ninh Son Ward, City. Tay Ninh, Tay Ninh.

- Representative office: 374 - 374B Vo Van Tan, Ward 5, District 3, City. HCM.

- 0961 416 688 - (0267) 3822 426

- Email: info@greenpackaging.vn